/chemical-reaction-pipette-0-5m-solution-of-copper-sulfate--cuso4--into-0-5m-solution-of-sodium-carbonate--na2co3---blue-copper-carbonate-precipitate--cuco3--formed-result--cuso4-na2co3--cuco3-na2so4-667616695-59e0f159d088c00011b1235a.jpg)

A problem that arises is the reactivity of the elemental particles with atmospheric oxygen. The domain magnetization of elemental iron or cobalt exceeds that of magnetite at normal temperatures by three to fourfold giving incentive to the preparation of more highly magnetizable ferrofluids containing these metals. Oversize material can be removed by centrifuging or with magnets and the concentration of particles adjusted by the evaporation or addition of the carrier solvent. A representative composition consists of magnetite particles, oleic acid dispersant, and an aliphatic hydrocarbon carrier such as hexadecane.

After a prolonged period of grinding in a ball mill (500–1000 h) near-quantitative conversion of the feed solids to colloidal particles of the order of 9–10 nm results. The proportion of dispersant to solid corresponds closely to a monolayer coating on the particles in the product liquid. In the grinding process, magnetic powder, most commonly magnetite of several microns size, is mixed with 10–20 vol.% of dispersing agent based on solvent volume, and 0.2 kg l -1 of magnetite may be used. In this manner, ferrofluids can be conferred stability over ranges of pH values. Massart (1996) discusses procedures for bonding species of small ions of a desired electrical sign to the surface of oxide particles. Following precipitation in the procedure of Khalafalla and Reimers (1974) the small particles are extracted into a mixture of surfactant in an organic solvent. The iron salts used in the preparation may be any combination of soluble salts such as the chlorides or sulfates and the alkali can be ammonium hydroxide, sodium hydroxide, or another base. Where FeO.Fe 2O 3 is magnetite written to emphasize the ratio of divalent to trivalent iron atoms in it, Fe III/Fe II=2. Most process wastewaters contain mixed metals and so precipitating these different metals as hydroxides can be a tricky process ( Lewinsky, 2007).

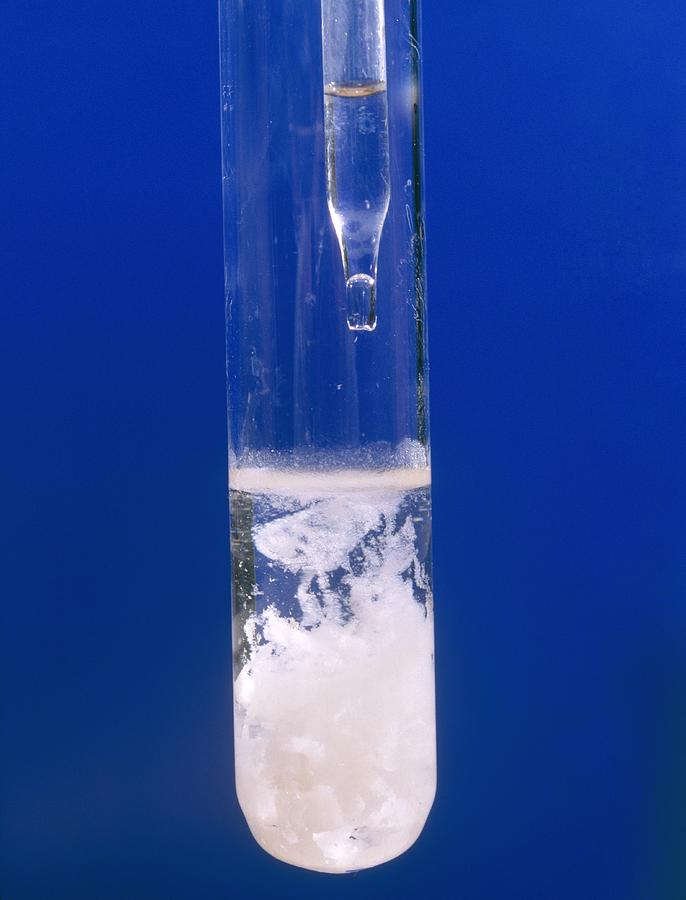

Therefore, the optimum pH for precipitation of one metal may cause another metal to solubilize or start to go back into solution. Metal hydroxides are amphoteric, which means that they are increasingly soluble at both low and high pH values. Each dissolved metal has a distinct pH value at which the optimum hydroxide precipitation occurs-from 7.5 for chromium to 11.0 for cadmium. The most widely used chemical precipitation process is hydroxide precipitation (also referred to as precipitation by pH), in which metal hydroxides are formed by using calcium hydroxide (lime) or sodium hydroxide (caustic) as the precipitant. The effectiveness of a chemical precipitation process is dependent on several factors, including the type and concentration of ionic metals present in solution, the precipitant used, the reaction conditions (especially the pH of the solution), and the presence of other constituents that may inhibit the precipitation reaction. The unit operations typically required in this technology include neutralization, precipitation, coagulation/flocculation, solids/liquid separation, and dewatering. The particles formed by this reaction are removed from solution by settling and/or filtration. The ionic metals are converted to an insoluble form (particle) by the chemical reaction between the soluble metal compounds and the precipitating reagent. Yaser Dahman, in Nanotechnology and Functional Materials for Engineers, 2017 6.3.2.2.1 Chemical precipitationĬhemical precipitation is the most common technology used in removing dissolved (ionic) metals from solutions, such as process wastewaters containing toxic metals.

0 kommentar(er)

0 kommentar(er)